To establish the hem bend line add the two outside dimensions up to the hem then subtract half the hem elongation allowance and a full bend deduction for the inner 90 degree bend.

How to put a hem on sheet metal.

To establish the inner smaller radius 90 degree bend line subtract half a bend deduction from the outside dimension of the flange.

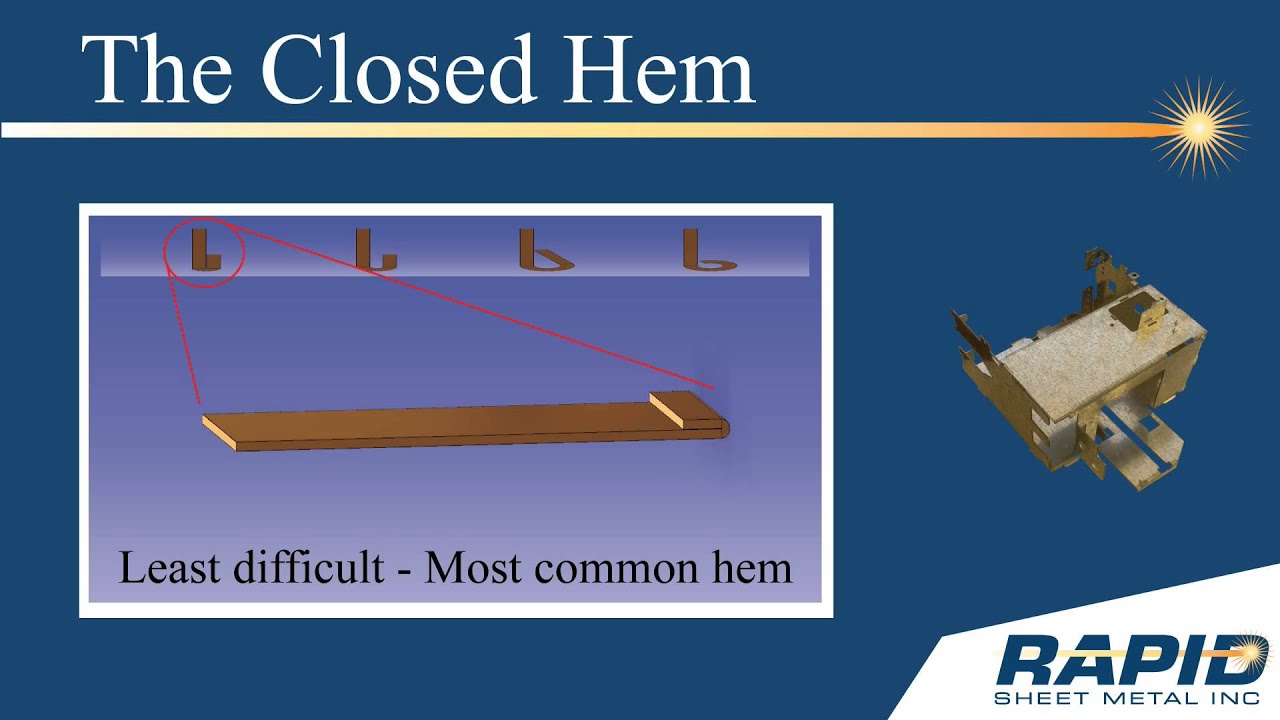

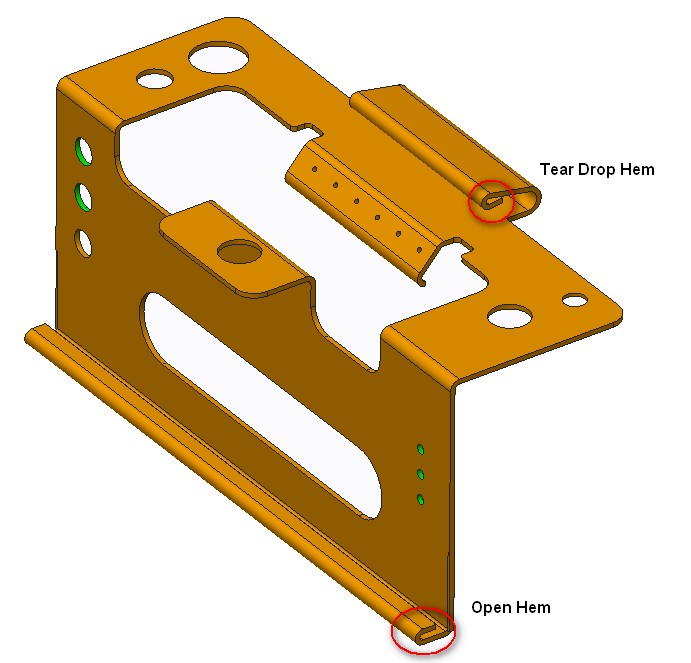

The cad hem s angle can be adjusted past 180 degrees to create a closed teardrop or underbent to create an open hook.

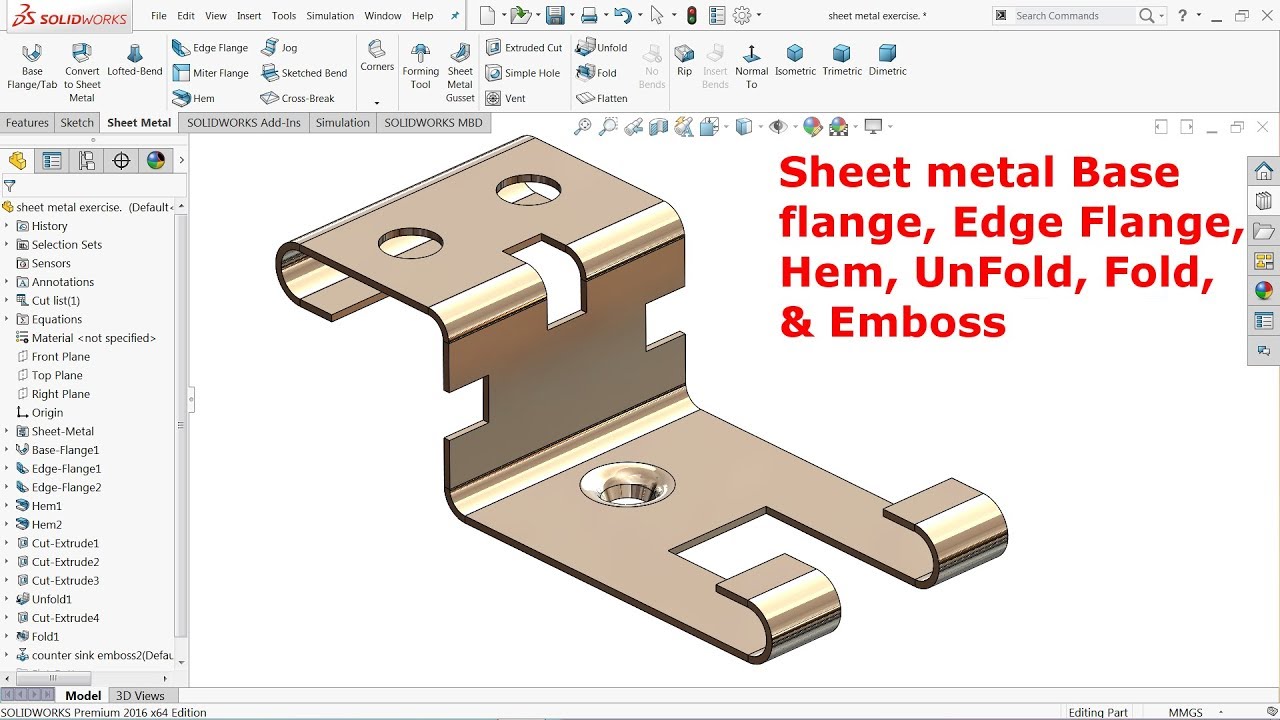

The hem tool adds a hem to your sheet metal part at a selected edge.

To bead an edge simply select that hem type in the hem feature s setup.

In an open sheet metal part and in the graphics area select an edge as shown.

You can create single double rolled and teardrop hems.

Create a bend with acute angle tooling in the metal 30 is preferable but 45 will work for some circumstances.

In the type drop down list click one of the following.

Step 10 repeat the last step again but this time try a different type of hem.

As shown in figure 1a pick an edge or edges set a depth and decide on the gap.

When working with a brake press hems are always created in a two step process.

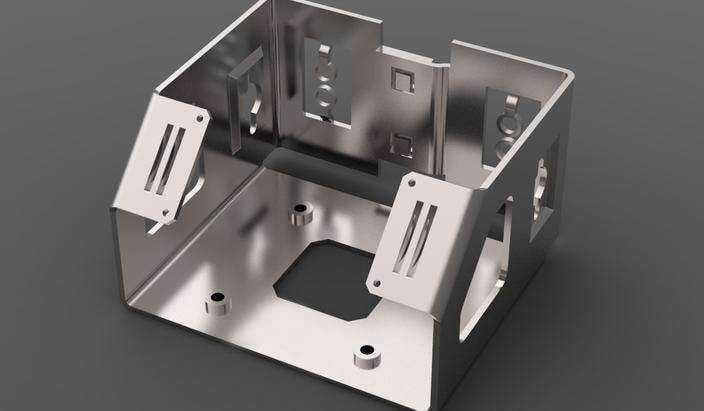

A hem provides stiffness to a design or provides a smooth rounded external edge on a part to eliminate sharp edges.

On the ribbon click sheet metal tab create panel hem.