Using a filling primer would probably result in still being able to see the pits to a certain extent.

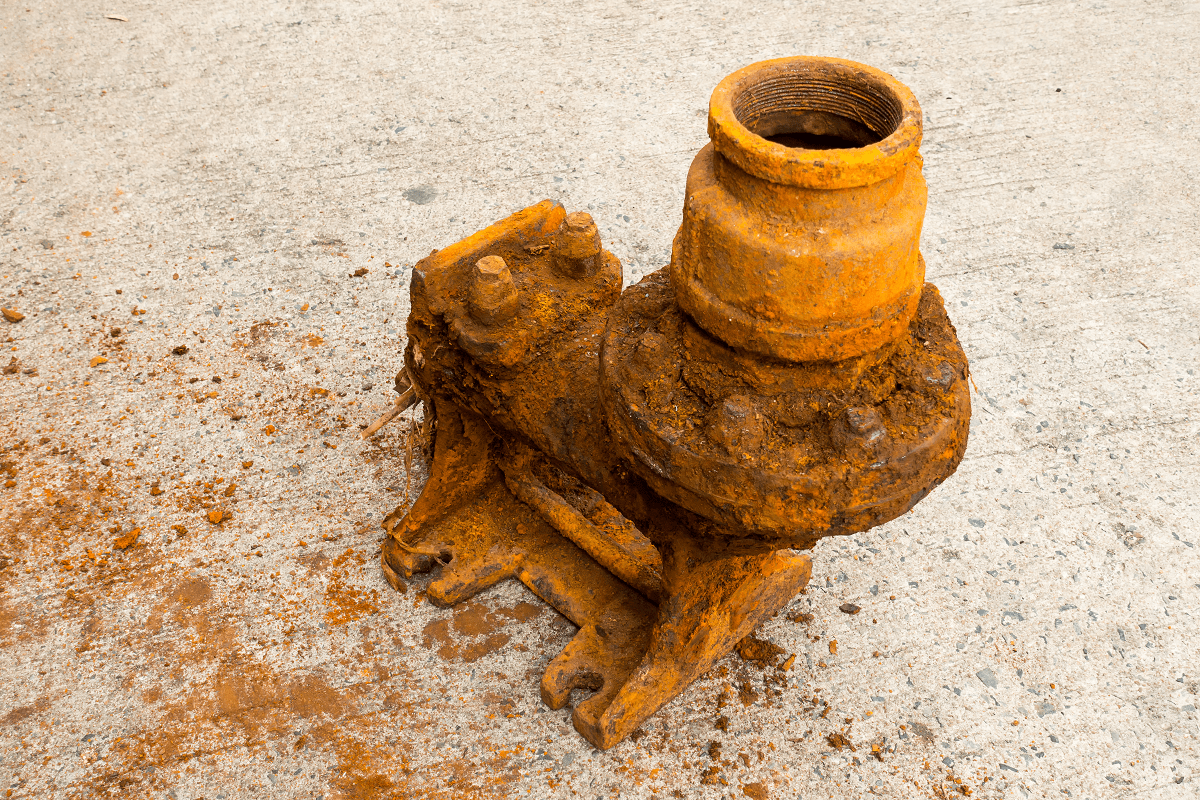

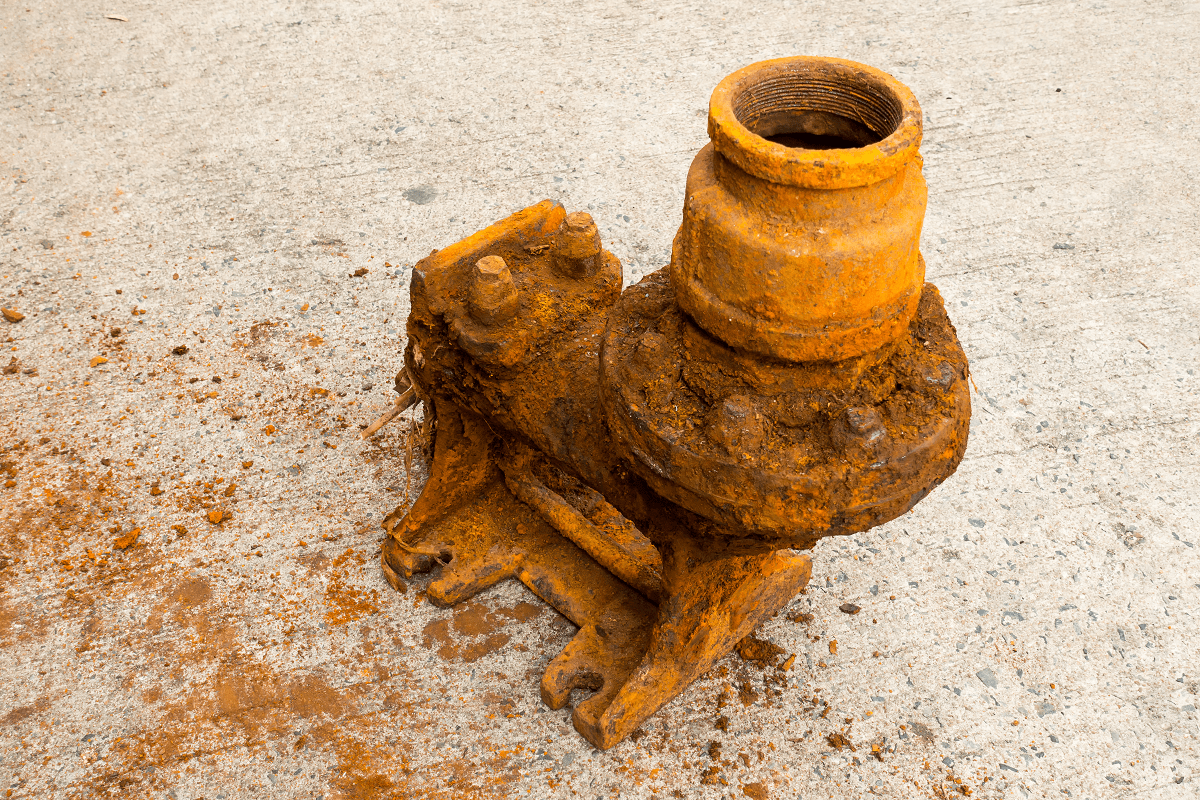

How to repair pitted sheet metal.

Cover the area with plastic wrap to prevent the fast etch from evaporating before it can work.

Attach the wire brush to the drill and apply to the metal.

The sand paper can be held in your hand for smaller.

Assuming that your metal is still strong enough i would use a polyester sot putty which is basically a very fine grained body filler that is slightly easier to sand.

Grind down heavily rusted metal spots faster with a wire wheel and a drill or angle grinder.

Wrap a sheet of 80 grit sandpaper around a sanding block and sand the pitted area aggressively.

Sand the area again with a fine grit sand paper to.

Apply eastwood fast etch to the area with the rust pits.

Mix the correct ratio of two part auto body repair filler and hardener as determined by the product.

Then paint it with fiberglass resin like you use to glass stuff only without the cloth then give it a skim coat of mud or bondo or whatever they call it where you are from.

Sand the area with a coarse grit sand paper using a circular motion.

Power brush the rusted areas with the wire brush on the power drill to remove the loose rust and flakes from the sheet.

You got to seal it or the rust will come back.

Give it a serious cleaning mayhaps some naval jelly or some other type of rust remover.

Work on the worst affected areas first removing as much of the rust and flaking metal as possible.

How to fix pitting in metal before painting clean.

Work outward and then return as you remove the pitting from the metal.

Fast etch eats into the rust dissolving it and leaving clean metal behind.

In order to properly treat fill and prep the fender just follow these easy steps.

You can use a.